Shaft Weld-overs

Shaft weld-overs, also known as cladding (or incorrectly “metalizing”), is the process of repairing a worn or damaged area on a propeller shaft or rudder shaft. Stainless steel shafts can be damaged by excessive wear in contact areas, such as bearings or seals, due to long life or misalignment. Shafts can also be damaged from crevice corrosion or stray current corrosion.

Typically, if the wear is smooth and less than 0.010″ deep it is acceptable. Deeper wear can affect the clearances in a bearing area . Any crevice corrosion, stray current corrosion or wear in a lip seal area must also be repaired since seals such as Tides Seals need a smooth surface to maintain water tight integrity. If the corrosion is in a packing area the flax packing life will be greatly reduced due to accelerated wear.

To repair a shaft it must be placed in a lathe and have the damaged area turned down approximately 0.125″. The area is built back up using semi-automatic MIG welding while slowly turning in the lathe. After overnight cooling, the shaft is turned back down to close to the original shaft diameter. However, applying the extreme heat of welding to an area close to the shaft end will inevitably put a bend in the shaft. So the shaft must be straightened before putting back into the lathe for the final machining and polish.

Expert weld-overs cannot be detected by eye or feel once complete.

- Repair area cut back and prepped on lathe

- Chris Z expertly builds up the repair area

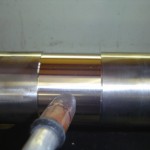

- Welding complete – cooling down

- First pass machining back to spec

Click to watch the video of a day at High Seas Yacht Service.

Click to watch the video of a day at High Seas Yacht Service. Click to watch Marine Industries Association of South Florida video featuring Salty Jobs at High Seas Services.

Click to watch Marine Industries Association of South Florida video featuring Salty Jobs at High Seas Services.